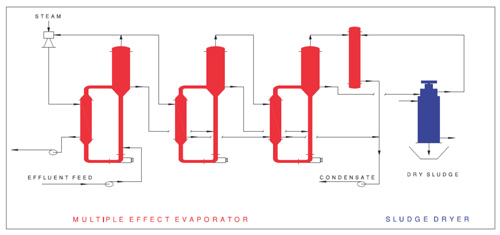

MEE will be falling film evaporator or forced circulation evaporators in series with or without thermo compressor to get steam economy. No.of effects will be optimized based on total evaporation load and cost of steam & power at site

MEE will be falling film or forced circulation evaporators in series with or without thermo compressor to get steam economy. No.of effects will be optimized based on total evaporation load and cost of steam & power at site