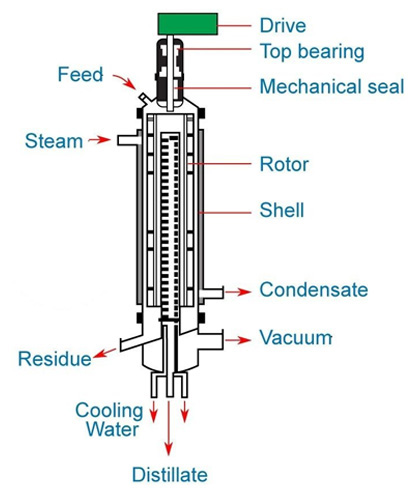

The Wiped Film Evaporator (WFE) is used for concentration, distilling,

stripping, dehydration and deodorisation of products which are heat sensitive or

viscous. The equipment can handle a very wide range of feed compositions ranging from 1%

to over 95% concentration. WFE has several advantages as stated in the table below. The

operation is continuous with a single pass; the self cleaning continuous contact wipers

produce and renew the thin film. Such an operation improves product yield, avoids

residue and colour formation. It has an internal condenser (optional) that minimizes the

pressure drop and maintains vacuum.