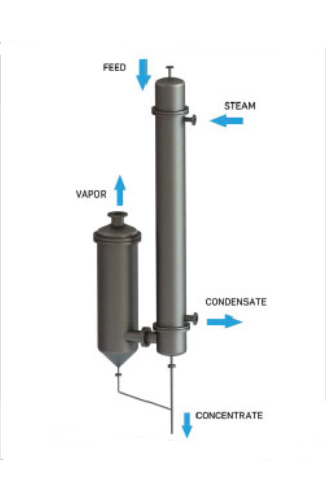

The Falling Film Evaporator (FFE) are vertical shell and tube heat exchangers designed with a vapor-liquid separator to efficiently separate the vapor from the remaining liquid. In an FFE, the feed liquid is introduced at the top, descending along the inner surface of the heated tubes as a thin film, while the co-current flow of generated vapors increases turbulence, thereby optimizing heat transfer. In an RFE, the liquid is fed from the bottom of the tubes; as it is heated, the resulting vapors lift the liquid upward, generating high velocities that enhance thermal efficiency. Both configurations utilize the vapor-liquid separator to effectively separate the vapor from the residual liquid.