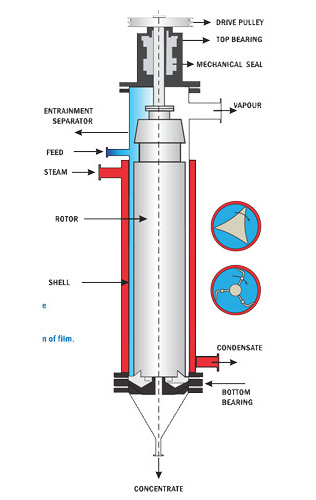

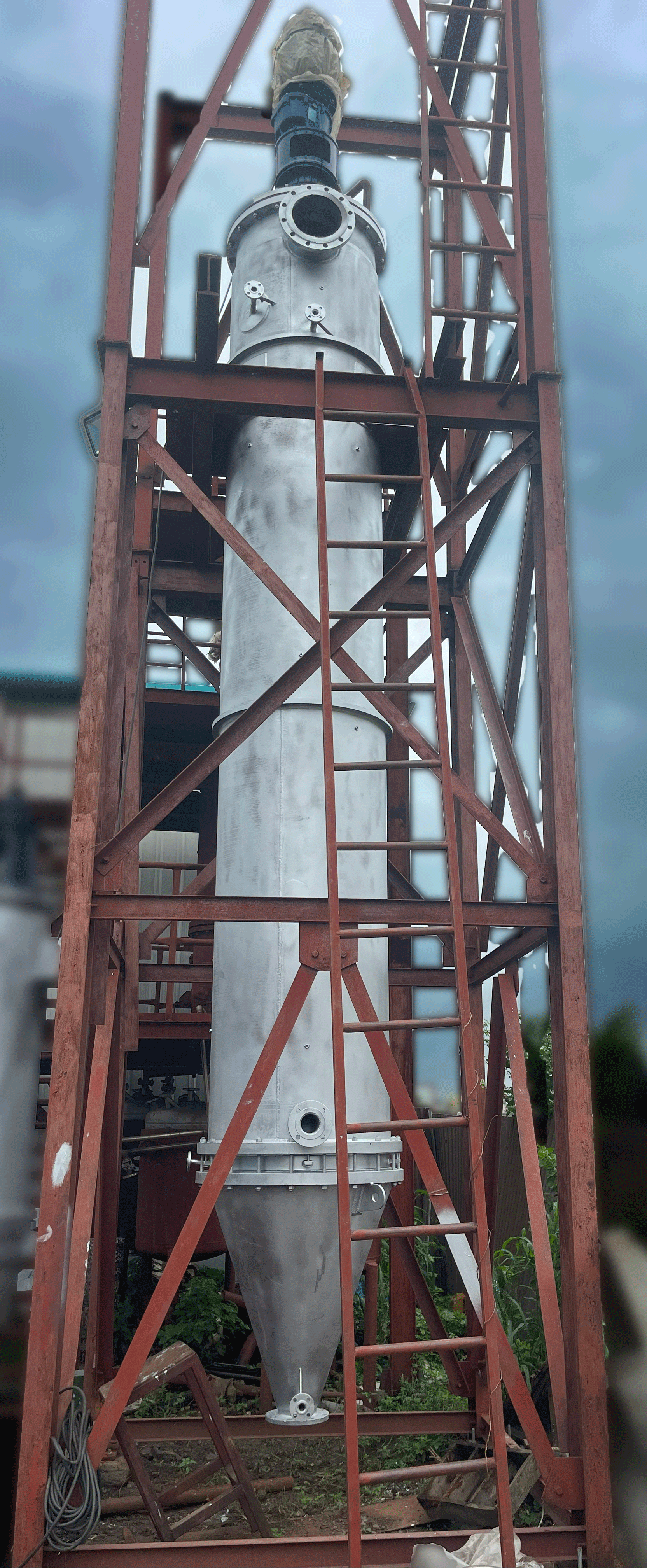

An Agitated Thin Film Evaporator (ATFE), also known as a Thin Film Evaporator (TFE) or Wiped Film Evaporator (WFE), comprises a jacketed shell that is precisely machined on the interior surface and a rotor with blades that maintain a minimal gap from the shell.

A feed distributor at the inlet ensures the liquid is evenly spread into a thin film over the heated wall. The high-speed rotor then enhances the distribution and provides vigorous agitation as the film moves downward. The resulting vapors flow in a counter current direction and are effectively separated from any entrained droplets by an integrated entrainment separator.